Bar & Tube Straightening Presses

Traveling Gantry Narrow Bed Straightening Press

Savage’s narrow bed TFS Straightening Press is the perfect solution for straightening heavy shafts, tubes, and bars. The tube straightening press is loaded onto pressing anvils. The gantry is then traversed over the shaft. Straightening accessories include: Power workpiece rotation, power lift, power anvil positioning, and power rotation stand positioning along the bed.

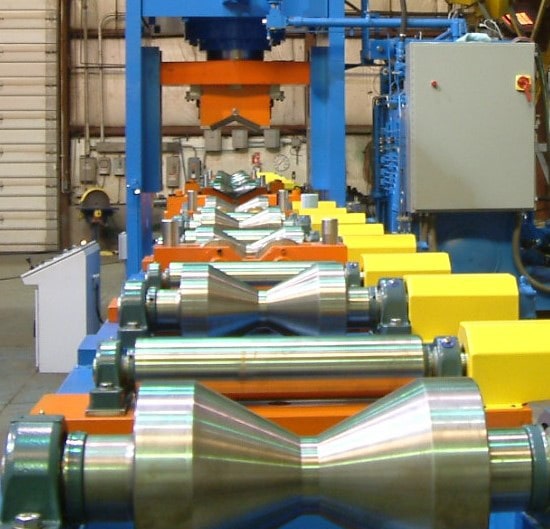

The 500-ton Round Bar straightening machine (left, top) is used for straightening round bars and tubes, and the 1000 ton press (left, bottom) was designed and built for Watervliet Arsenal in New York for straightening cannon barrels.

- Ram stroke control to .001″ prevents over bending of a workpiece.

- Powered lift and rotation of the workpiece.

- V-Blocks and rotation fixtures powered for left and right travel.

- Joystick controls ram movements.

- Traveling gantry and traveling platform.

- Remote pendant control. Radio control available.

- Straightening drill tools, drill pipe, bars, and tubes.

Catalog Information on Traveling Gantry Narrow Bed Straightening Presses

Catalog Information on Straightening Accessories for Traveling Gantry Narrow Bed Straightening Presses

Video - Watch Them Operate!

Video - 1500 ton Cannon Barrel Straightening Press

C-Frame-Straightening-Press

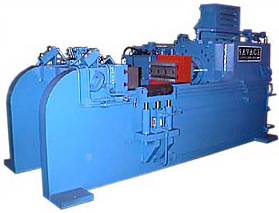

SAVAGE CFS C-Frame Straightening Presses are used to straighten round bars, shafts, tubes, and screws. Shafts can be straightened from their centers or from their O.D. All presses have 60″ wide beds for full tonnage (available to 96″) with extension tables available to support and indicate longer workpieces.

For the straightening of small shafts, we offer Savage CFS Straightening Presses. A full range of straightening accessories is available for the series including adjustable carriages, anvils, OD rotation fixtures, centering fixtures, and indicators.

The 40-ton model (left, top) features a complete C-Frame Straightening Accessories Package (left, bottom) including extension tables.

Catalog Information on C-Frame Straightening Presses

Catalog Information on C-Frame Straightening Accessories for Smaller Shaft Diameters

Catalog Information on C-Frame Straightening Accessories for Medium Shaft Diameter

Fixed-Frame-Straightening-Press

For straightening larger shafts, Savage offers the FFS Straightening Press. Roller stands permit crane loading and workpiece positioning under a fixed ram.

Savage’s model FFS Fixed Frame Straightening Press is an economical alternative to a traveling gantry press for straightening moderate-weight shafts, tubes, and round bars. In operation, the workpiece is loaded onto rollers on an extension table to allow dial indication. The moving lift/rotation stands allow bars weighing up to one thousand pounds to be easily rolled into a straightening position under the ram. V-Block Anvils steady the workpiece, allowing for maximum precision during straightening.

The workpiece must be manually positioned under the ram, by moving it across the rollers. This provides an economical method of positioning heavy workpieces. Lift cylinders are available in the press bed to raise the workpiece for positioning of the press anvils.

The 100-ton model (left, top) and 300-ton model (left, bottom) both feature a complete Fixed Frame Straightening Accessories Package (left, bottom).

Catalog Information on Fixed Frame Straightening Presses

Fixed Frame Straightening Accessories

Video - Watch Them Operate!

Hybrid-Straightening-Press

For straightening larger shafts, Savage offers the Hybrid Straightening Press. Roller stands permit crane loading and workpiece positioning under a fixed ram.

Our Hybrid Straightening Press is a fixed frame round bar straightening machine with powered accessories for straightening heavy shafts, tubes, and round bars. It enhances the straightening process with traveling gantry-style powered accessories on the bed but goes further still with a powered bar feed. In operation, the workpiece is loaded onto rollers on the extension table. Even bars weighing thousands of

pounds can easily be positioned under the ram via the powered rollers.

The powered rollers allow the operator to position the workpiece under the ram, providing an efficient and economical method for positioning heavy workpieces. Lift cylinders are available in the press bed to raise the workpiece for positioning of the press anvils.

The 1800 ton model (left, top) was built for Patriot Forge, complete with Hybrid Straightening Accessories Package (left, bottom).

Catalog Information on Hybrid Straightening Presses

Watch Them Operate!

Horizontal-Bulldozer-Straightening-Press

Savage horizontal presses are generally used for straightening or bending structural materials. Our round bar straightening machines are available in a variety of configurations. Options include conveyors, powered work lifters, powered work rotators, moveable anvil blocks, guided ram, t-slotted bolsters, and pushbutton or lever controls.

This 400-ton model (left) was designed to bend gentle curves into railroad tracks for Progress Rail Services.

Available Frame Types:

- Traveling Gantry Narrow Bed Straightening Press

- C-Frame Straightening Press

- Fixed Frame Straightening Press

- Hybrid Straightening Press

- Horizontal Bulldozer Straightening Press

Capacities

Tonnage and Bed Sizes are Designed to Meet Your Requirements

Designed to Fit YOUR Application

C-Frame, Fixed Frame, and Hybrid Presses allow the work to be pulled on rollers under the ram.

Savage has developed Narrow-Width Straightening Presses and Accessories Packages for straightening shafts, tubes, bars, and small castings. Precision digital stroke control (via setpoint) comes standard with these frame types, and is cost-effective compared to the competition, all without the utilization of dirt-sensitive Servo-proportional valving.

- Easy operation

- Bed size, daylight opening, throat depth, speed, and stroke available to meet any requirement

- .001” stroke control for accurate ram positioning and preventing over-bending the workpiece

- Ergonomic operator’s control station

- Rugged, computer-designed frame for low-stress levels

- Self-contained hydraulics

- Feed equipment available

- Made in the USA

Savage does not stock catalog sizes. Each round bar straightening machine is engineered to your specifications to perform your job at maximum efficiency. For more information on our round bar straightening machines and tube straightening presses, please contact the team at Savage Engineering.

Industries Served

- Offshore Drilling

- Oil & Gas

- Mining

Client History

- Annison Army Arsenal

- APS Technologies

- ATI Wah Chang

- AW Miller

- Basintek

- Boeing

- Brunner

- Brush Engineered Bronze

- Brush Wellman

- Conbraco Industries

- Dehavilland

- Dyna Drill

- Dynamic Flowform

- Eastman Kodak

- FMC Arabia

- General Electric

- Giddens Industries Inc.

- GM CPC

- GM / Tonawanda

- HDH Instruments

- Halliburton

- Hughes Tool

- Hunting Dearborn

- Kawasaki Motors Manufacturing Corp.

- Kurtz Steel

- LB Steel Plate Company

- Logan Oil Tool

- Michelin Tire Corporation

- Micro Tool

- Northlake Steel

- P & H Mining

- Patriot Forge

- Pro Machine LP

- Raymond Corporation

- SPX

- Schlumberger

- Specialty Bar Products

- Standard Steel Specialty

- Thomson Corporation

- Trident

- Trinel

- United States Coast Guard

- United States Navy

- Universal Stainless

- Watervliet Arsenal

- Weatherford

- Westinghouse

- Western Reserve

- Weatherford

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE-PRONE CASTINGS ARE USED

IN ANY OF OUR PRESSES.

CONTACT US NOW

to Discuss Your Application