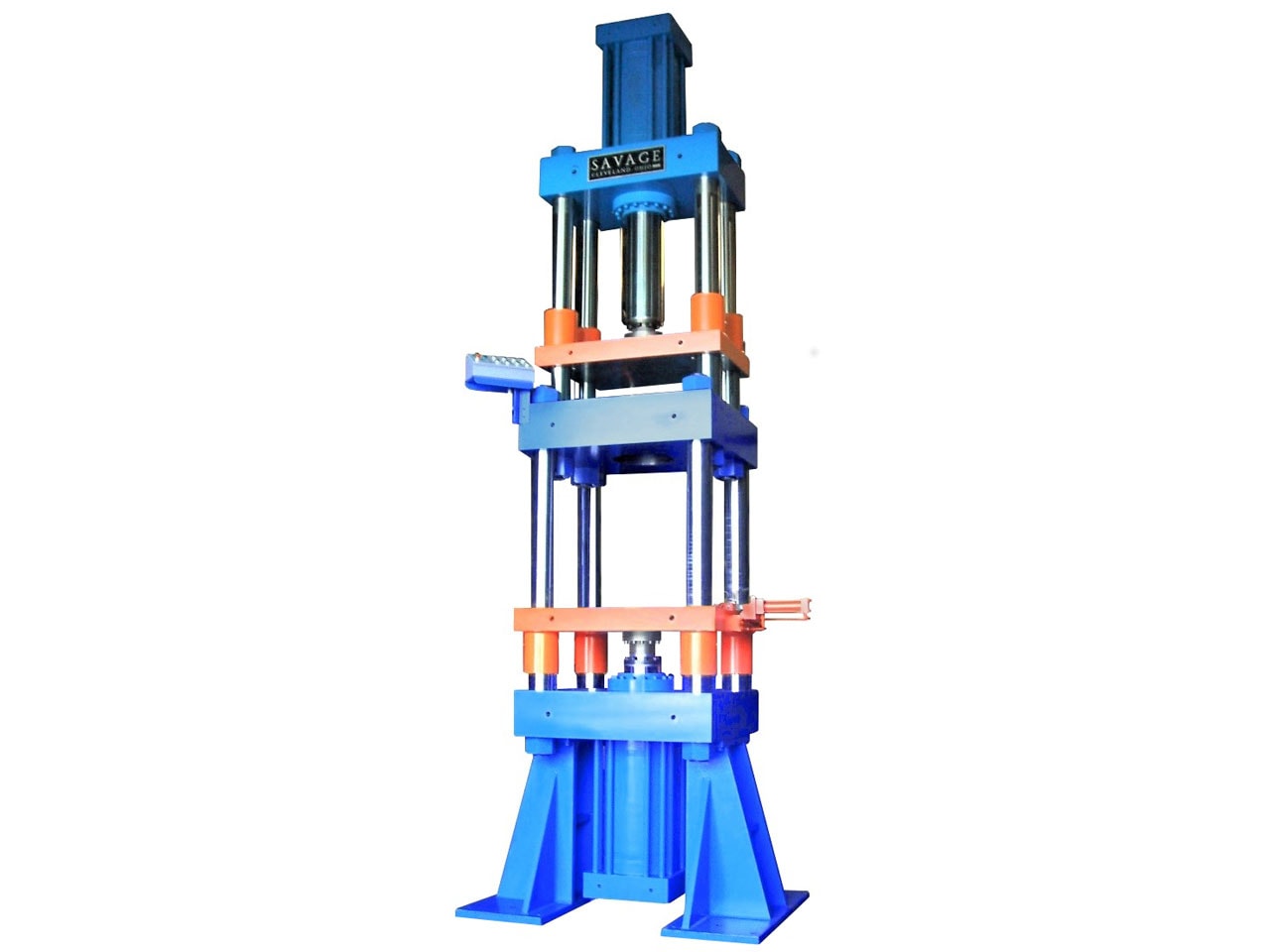

Opposed Ram Compacting Press

For Explosives Compaction and Powder Compaction

What Is A Compaction Press?

Savage offers three different types of compaction presses to suit different needs: single ram compaction presses, opposed ram compacting presses, and hazardous-rated presses for explosives compaction. All compaction presses have a 4-post frame construction. Options and upgrades include computer storage of setpoint programs to calibrate speeds, pressures, dwell times, vacuum, tool temperatures, and quantity of pressure/hold applications.

Single ram compaction presses are appropriate for producing relatively thin compacts of uniform density that do not require the use of equal pressure from opposing sides. The opposed ram compaction press design utilizes dual, vertically-opposed rams for thicker compacts and/or larger compaction ratios that require a deep tool cavity. Savage Hydraulic Presses for Explosive Compaction are rated for hazardous locations using intrinsically safe signals. Local electrical components are typically housed in air-purged NEMA 12 or dust-proof NEMA 9 enclosures to meet hazardous location ratings.

Applications

Single ram compaction presses feature a lower ejector and are well-suited for compacting basic materials into thinner compacts. This design also lends itself to heated tool applications.

Opposed ram presses allow compaction from both ends of the tool cavity resulting in a more even density on thick compacts. The lower ram doubles as an ejector.

The incorporation of explosion-proof components and controls equips this specialized machinery to compress and compact highly sensitive materials for:

- smart bombs

- warheads

- rockets

- grenades

- pyrotechnics

- munitions

- countermeasures / flares

- flash bangs/smoke bombs for riot control.

Savage has experience with the compaction of materials including metal powders, graphite, ceramics, boron nitride, carbide, PBX, titanium and titanium sponge, molybdenum, and Teflon. The uniform force of opposed rams creates the ability to compact nearly any loose material.

Features and Benefits

Savage’s pressures for explosive compaction offer the following standard features and optional equipment:

- Self-aligning split coupler increases cylinder rod seal life

- Opposed guided platens/rams increase product uniformity

- Fixed center platen contains tool cavity

- Positive stops are available to eliminate over-travel

- Oversized footpads minimize floor loading

Powder compaction presses are also available with integral sliding fill shoes, weigh feeders, hoppers, ejectors, shuttles, and conveyors.

In addition, Savage’s Compaction Presses are designed to meet your exact product requirements. We’ll work with you to customize:

- Stroke length

- Upper shut height

- Lower daylight opening

- Hazardous location-rated controls

- Tonnage

- Bed size

- Speeds

- Work height

Why Chose Us?

For nearly 60 years, Savage Engineering has been designing and building high-quality hydraulic presses to meet each customer’s unique needs and exact job specifications. Our process is fully integrated from concept to delivery. You’ll receive onsite installation, training, and technical support throughout the operating life of your press.

All Savage presses are made in the USA. We are committed to your complete satisfaction and success. Let us design the machine your business deserves!