Powder Compacting Presses

Powder and Explosives Compaction Presses

Savage Powder Compacting Presses are designed for compacting explosive powders, bulk materials, friction materials, free-flowing materials, metal powders, titanium sponge, carbon, graphite, boron nitride, etc. We offer single or opposed compacting rams, ejectors, compaction tools, feeders, and remotely controlled electronics to meet your powder and explosives compaction needs.

Our Custom Powder Compacting Presses are available with hoppers, fill shoes, ejectors, shuttles, and conveyors, as well as with volumetric or loss-in-weight feeders. Three-piece powder dies are available with a floating or a fixed cavity, stripper, and punches.

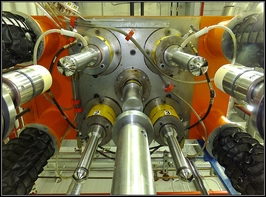

Opposed Ram Compaction Presses allow for two modes of operation; both rams can compact simultaneously, or one ram can remain fixed while the other ram compacts.

Powder Compaction Slab-Side Press

This style of Powder Compaction Press produces larger-sized compacts in a segmented die which shuttles out. The die then splits open to expose the compact which can be easily lifted out, eliminating the need for a high-tonnage ejector which must be installed below floor level.

This 500-ton model (left) automatically feeds a weighed charge of powder into a segmented mold. Up to 500 tons of pressure compact the powder into shape. The mold segments automatically open, the press ejects the part, and shuttles back for a refill from a loss-in-weight feeder.

Catalog Information on Powder Compaction Slab-Side Presses

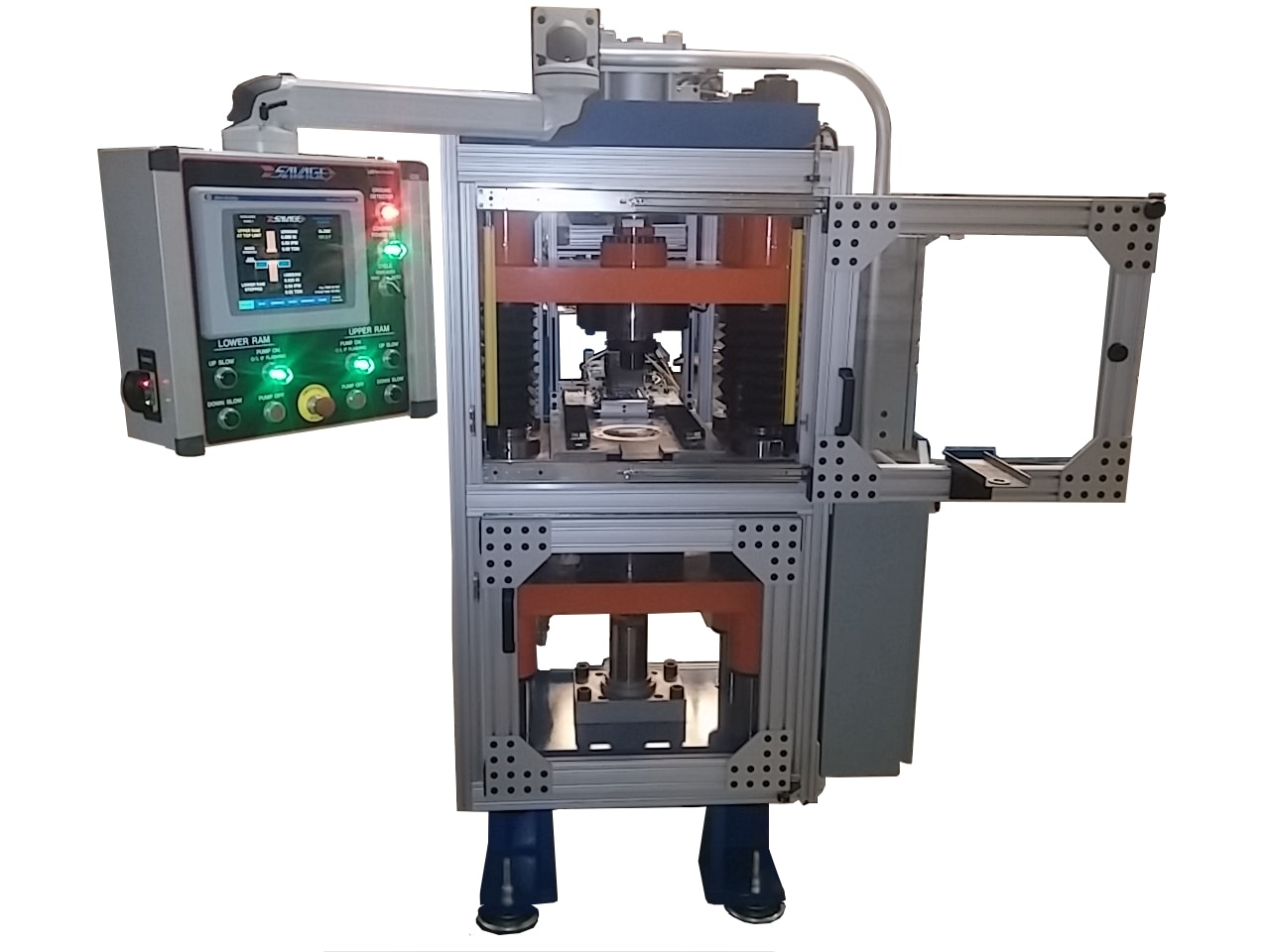

40/40 Ton Opposed Ram Powder Compaction Press

This 40/40 ton Opposed Ram Powder Compaction Press (left), designed for Sandia National Laboratories, features opposed rams with a fixed center tool holder and fluidized fill system for product uniformity. This design allows compaction from both ends toward the center for improved density throughout.

Catalog Information on 40/40 Ton Opposed Ram Powder Compaction Press

Watch Them Operate!

Explosives Compaction Press

SAVAGE Explosives Compacting Presses feature single or opposed compaction rams and ejectors, tailored for your application. Setpoint programs for programmable speeds, pressures, dwell times, vacuum, tool temperatures, and quantity of pressure/hold applications are stored remotely via computer. This 300-ton Explosives Compaction Press produces LAW Rocket compacts for the United States military.

Catalog Information on Explosives Compaction Press

Watch Them Operate!

Available Frame Types:

- Powder Compaction Slab-Side Press

- 40/40 Ton Opposed Ram Powder Compaction Press

- Explosives Compaction Press

Capacities

Tonnage and Bed Sizes are Designed to Meet Your Requirements

Designed to Fit YOUR Application

Savage Powder Compaction Presses are designed to your requirements and are capable of compacting a wide variety of substances:

- Bulk Materials

- Friction Materials

- Free-flowing Materials

- Powdered Metal

- Titanium Sponge

- Carbon

- Graphite

- Boron Nitride

- Explosive Powder Billets

- Pyrotechnics

- Munitions

- Countermeasures

Industries Served

- Automotive

- Chemicals

- Consumer Goods

- Medical Devices

- Military & Defense

These machines are designed to simplify the compaction process, eliminating the lifting of heavy compacts and the over-handling of hazardous materials.

- 50 to 2000 ton capacity

- Rugged straight side or 4-post design.

- Hydraulic ejector

- Hopper and sliding fill shoe feeder

- Fluidized fill shoe

- Fully automatic cycle with ejection

- Optional remote controls for explosives compaction

- Stroke, daylight, speeds, and bed sizes to your requirements

- Made in the USA

Savage does not stock catalog sizes. Each press is engineered to your specifications to perform your job at maximum efficiency.

Client History

- Bettis Laboratories

- Day and Zimmerman

- Ensign Bickford A&D

- GE Healthcare

- Honeywell

- ICI Americas

- Los Alamos National Laboratories

- Sandia National Laboratories

- Union Carbide

- United States Navy

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE-PRONE CASTINGS ARE USED IN

ANY OF OUR PRESSES.

CONTACT US NOW

to Discuss Your Application