Metalworking Hydraulic Presses

Savage Engineering’s custom metalworking hydraulic presses are available in Four-Post Guided Platen and Straight Side Gib-Guided frame types. Applications include forming, stamping, blanking, bending, piercing, punching, perforating, trimming, transfer, flanging, joggling, forcing, and others.

Our custom metal forming hydraulic stamping presses have large-diameter, chrome-plated tie rods run through eight line-bored bronze bushing assemblies that guide the platens, ensuring positive alignment of all four posts. An extra-long guide bushing tube separates each pair of bushings for a generous bearing ratio.

Savage Straight Side Press fulfills applications where the tool is not guided, the load is not centered, multiple operations occur, or more accurate parallelism is required than a 4-post press offers. Straight side presses offer either 45 degrees or 8-way adjustable gibbing for a tight running clearance. Exclusive self-lubricating gib liners eliminate the need for lubrication systems.

Savage’s hydraulic stamping presses and Hydraulic Blanking Press employ robust straight side housing type construction with prestressed tie rods running through the side housing uprights. This type of construction is used on the most demanding applications with off-center loads or break-through shock. Blanking presses feature impact dampers to absorb break-through shock at its origin. They reduce stress on the press, dies, and foundation. They also minimize the noise produced during blanking.

Electro-hydraulic controls are available to make any or all of the press functions programmable. The Savage setup controller with a touchscreen operator interface is user-friendly. At the touch of a finger, the operator can change press set-ups from those stored in memory making set-up faster and consistently repeatable from job to job. Simply enter a job number assigned to a die and the hydraulic stamping press is ready to run. Optimum pre-established setpoints are automatically entered for tonnage, speed, positions, and dwell time values.

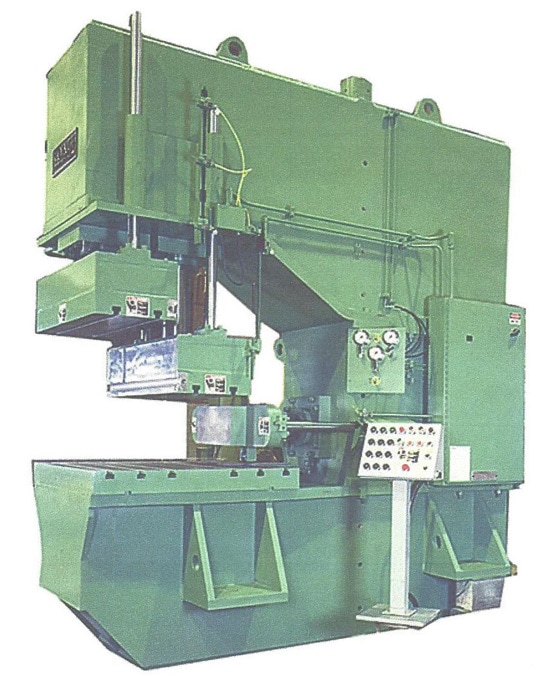

Straight-Side Press with Pre-Stressed Housing

Straight Side Pre-Stressed Housing Press frames employ rigid construction for low deflection levels and eight-way adjustable gibs on self-lubricated ways for precise parallelism.

This type of custom metalworking press is used for more demanding applications such as punching, blanking, trimming, piercing, perforating and multi-station dies.

The 350 ton model (left) is a high-speed, punch, bend, cut off, and emboss press with automatic 3/4″ x 4″ bar feeder for trailer hitch manufacturing.

Catalog Information on Straight-Side Presses with Pre-Stressed Housing

Straight-Side Gib-Guided Trim Press

These rugged machines are guided on eight-way adjustable gibs to ensure platen parallelism.

The 115 ton model (left) is a high-speed trim press for heavy cast-iron Honda automotive spindles. The 12″ thick solid bed has a through hole for part drop.

The slide is guided at the four corners on 45 degree adjustable gibs.

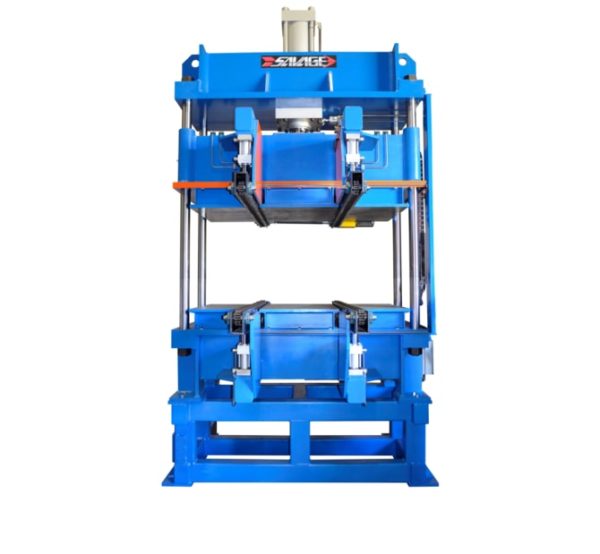

4-Post Press

Four-Post Presses are built with extra-long bushing tubes to separate eight (8) bronze bushings for parallelism and accuracy.

The 60 ton model (left) is used for blanking operations at the Thermos Corporation.

Catalog Information on 4-Post Presses

Straight-Side Hot Press with Pre-Stressed Housing

These metal forming hydraulic press machines feature a rigid, pre-stressed tie rod construction for the most demanding applications. This style of press is designed to combat adverse conditions such as offset loading, multiple station tools, and breakthrough shock.

This 400-ton model (left) was originally designed for Drop Dies and Forgings.

Catalog Information on Straight-Side Hot Presses with Pre-Stressed Housing

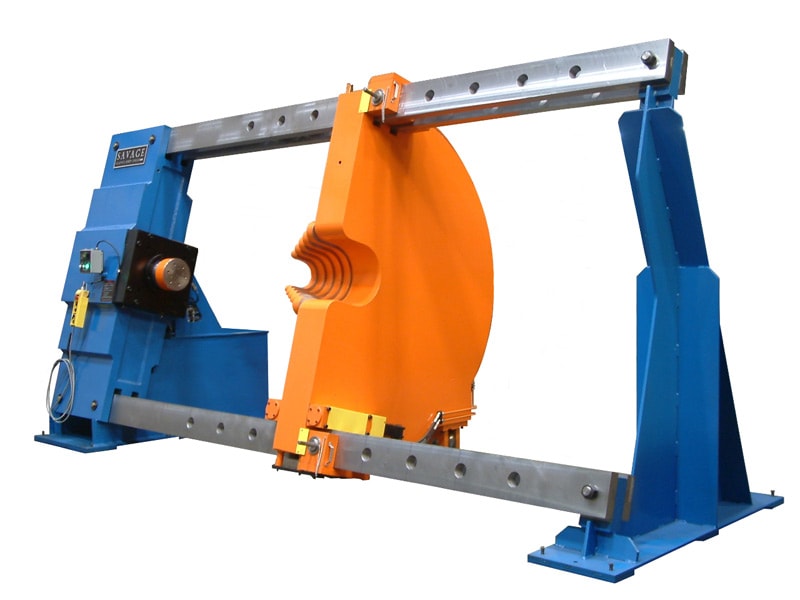

Wheel Press / Forcing Press

Horizontal Forcing Presses, also called Wheel Presses, are used to push/pull wheels, sheaves, gears, rolls etc. onto/off shafts or axles.

The 425 ton model (left) is inclined to allow for overhead loading, and features U-slot inserts and an open design which accommodate different shaft diameters and infinite shaft lengths.

Catalog Information on Wheel Presses / Forcing Presses

Technical Video

4-Post Metalforming Press with Hydraulic Cushion

Precision Four Post with extra-long guides, 120″ x 60″ diespace and fully guided hydraulic cushion. High speed hydraulics with fully programmable tonnage, speed and position with program storage, QDC and programmable stroke cushion.

The 1000 ton model (left) was designed and built for Rock Island Arsenal and features a 250 ton hydraulic cushion.

Catalog Information on 4-Post Presses with Hydraulic Cushion

C-Frame Flanging Press with Horizontal and Vertical Rams

This deep-throated press is generally used to form hull plate for ships or to form plate for heavy equipment and fabrication shops. Twin vertical 115 ton rams can be used separately in sequence or can be keyed together for a single 230 ton vertical platen.

A 60 ton horizontal ram allows intricate metal forming operations such as flanging, joggling, bending and forming heavy steel plate into complex configurations. These presses have three-piece frames held rigidly together with pre-tensioned tie rods.

The 230 ton model (left) was commissioned by the United States Navy.

Catalog Information on C-Frame Flanging Presses

Wheel/Axle Press: Double-Ended with Dual Rams

Double-Ended Wheel/Axle Mounting and Demounting Presses for LRV with dual PanelView Plus HMI stations and dual-sided Wheelset Recording Computers. Available with wheel, axle, and bearing automation, wheel staging racks, wheel loader, and laser measurement of track gauge, out of round, and radial / lateral runout.

Catalog Information on Double-Ended Dual Ram Wheel / Axle Press

Video - Watch Them Operate!

AVAILABLE FRAME TYPES:

DESIGNED TO FIT YOUR APPLICATION

Assembly Presses come in a wide variety of sizes and designs to meet your specific production needs. These specialty presses and assembly presses perform multiple steps to take multiple sub-components and assemblies and turn them into a final product. The frame types will differ depending on the specific application.

Options include index tables and material handling equipment. Custom-built Specialty Presses are also available to meet unusual requirements.

- Easy operation

- Bed size, daylight opening, throat depth, speed and stroke available to meet any requirement

- Rugged, computer-designed frame for low stress levels

- Self-contained hydraulics

- Feed equipment available

- 10 to 1200 ton capacity

- Overhead power unit minimizes floor space requirement.

- Long guide length.

- High Speed Hydraulics

- Removable T-slotted bolsters.

- Movable remote control station.

- Light screen barrier guards.

- Swing-in safety platen block available.

- JIC components.

- Made in USA

Savage does not stock catalog sizes. Each press is engineered to your specifications to perform your job at maximum efficiency.

INDUSTRIES SERVED

- Automotive

- Chemicals

- Consumer Goods

- Medical Devices

- Military & Defense

- Oil & Gas

- Railroad

- Transportation

- Steel

CLIENT HISTORY

- Advanced Assembly Auto

- Arconic

- ATI Wah Chang

- Clark Construction (for Bay Area Rapid Transit Authority)

- Colonial Supply Inc.

- Duer Carolina Coil

- Dynamic Materials

- Halliburton

- Hiruta Corporation

- King County

- Maquindus, C.A., Inc

- Martin Marietta

- Lufkin

- Lufkin GE

- Lufkin Romania

- Port Authority of Allegheny County

- Progress Rail Services

- Reliance Electric

- Weirton Steel

- United States Navy

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE PRONE CASTINGS ARE USED

IN ANY OF OUR PRESSES.

CONTACT US NOW

to Discuss Your Application