Hydraulic Assembly Presses

Savage manufactures a wide variety of hydraulic assembly presses for a full spectrum of industrial products. Savage is a custom assembly press manufacturer and offers them in C-Frame, 4-Post, and Straight Side constructions to meet your requirements. Options include index tables and material handling equipment. Special custom-designed presses are also available to meet unusual requirements. Applications of custom assembly presses include assembling, crimping, bending, staking, and riveting of parts as well as pressing bearings, seals, or bushings into your product.

Shuttle Press

Shuttle Bed Presses allow crane loading of heavy parts and promote safety since the shuttle allows the operator to keep hands out from under the ram. These machines can be used with or without dies for assembly, straightening, cutting, and more.

This slab side press (left) features a shuttle table and part indexer, designed for GM Corp. to rivet the ring gear to the yoke assembly.

C-Frame Assembly Presses

C-Frame Assembly Presses are well-suited for creating product lines of smaller parts and components, and can easily be repositioned on a shop floor to suit changes in production line requirements.

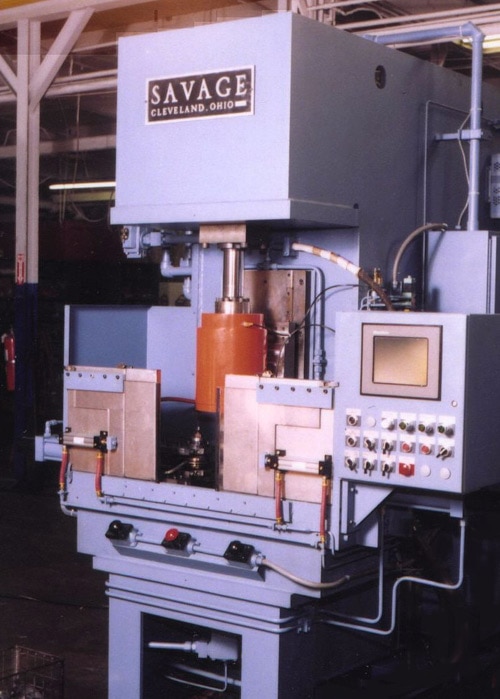

This line of 10-ton presses (left) press bearings into steering knuckles and hubs into the bearings for Chrysler Corp. (1998). These assembly presses feature load cells to measure the force (during assembly) and encoders to measure stroke attained during each cycle with “part accept/reject” acknowledgment of each cycle. Graphical waveforms provide “load” vs. “distance attained” information. Since the product is safety-related, a historical record is accumulated for each part.

Similar parts assembly presses at Ford Motor Co. assemble pistons onto rack and pinion steering sectors. Other applications include staking of brackets onto seat belts and crimping of tie rod/ball studs for Dana Corp. and TRW.

Specialty Presses

For the most unique applications, Savage will design and build an application-specific machine, or fully automated system, that satisfies the demands of our customer’s process.

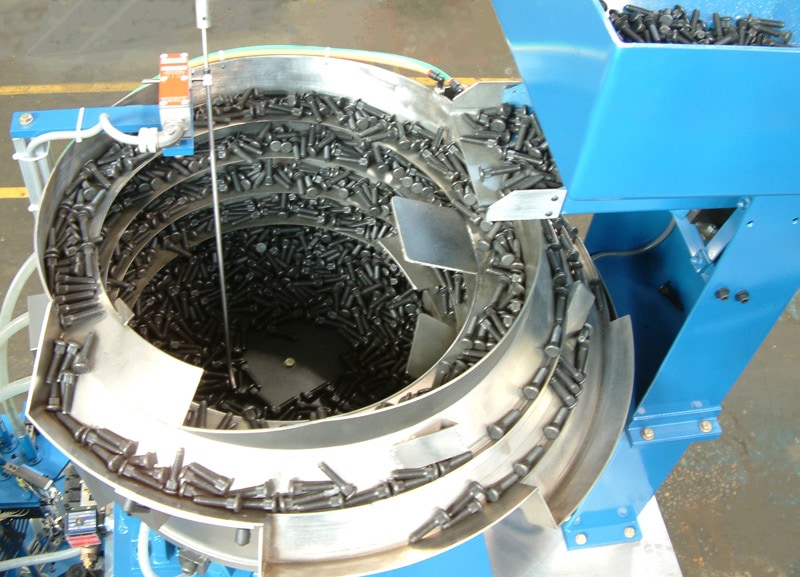

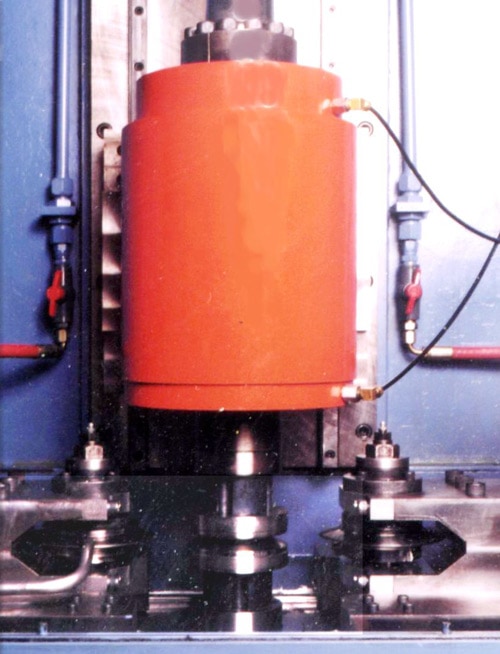

This 20-ton Specialty Press (left) is a fully automated stud pressing machine with a robotic bowl feeder (left, bottom), grippers, loaders, and unloaders.

Video - Stud Insertion Assembly Press

Pulley Splitting

Savage Engineering is a custom assembly press manufacturer that pioneered the Split Pulley machine over 40 years ago. Our Pulley Splitter combines automated hydraulics with superior frame construction, spindle, slide, bearings, and a guided design for increased accuracy, speed, power, and production.

This Savage specialty machine (left) splits steel disks to manufacture V-pulleys for the lawn and garden industries. The heavy-duty design incorporates massive spindles and bearings on the form and cutter rolls which allows higher RPM. This faster cycling makes Savage the most productive splitter available. Computer-controlled feeds and program storage for each part number.

Video - Pulley Splitter

Available Frame Types:

Capacities

Tonnage and Bed Sizes are Designed to Meet Your Requirements

Designed to Fit YOUR Application

Assembly Presses come in a wide variety of sizes and designs to meet your specific production needs. These specialty presses and assembly presses perform multiple steps to take multiple subcomponents and assemblies and turn them into a final product.

The frame types will differ depending on the specific application.

Options include index tables and material handling equipment. Custom-built Specialty Presses are also available to meet unusual requirements.

- Easy operation

- Bed size, daylight opening, throat depth, speed, and stroke available to meet any requirement

- Rugged, computer-designed frame for low-stress levels

- Self-contained hydraulics

- Feed equipment available

- Made in the USA

Applications include:

- Assembling

- Crimping

- Bending

- Staking

- Riveting of parts

- Pressing bearings, seals, or bushings into your product

Savage does not stock catalog sizes. Each press is engineered to your specifications to perform your job at maximum efficiency.

Industries Served

- Automotive

- Chemicals

- Consumer Goods

- Medical Devices

- Military & Defense

Client History

- Champion Spark

- Chrysler

- Dana

- Ford

- Giddings and Lewis

- Gilman

- Gunnite

- Micro Pump

- Nippondenso

- MIC Group

- Pratt and Whitney

- Stamtex

- TRW

- Warner Robbins AFB

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE-PRONE CASTINGS ARE USED IN ANY OF OUR PRESSES.

CONTACT US NOW to Discuss Your Application