Savage Engineering History

We build the machines that the other guys can’t.

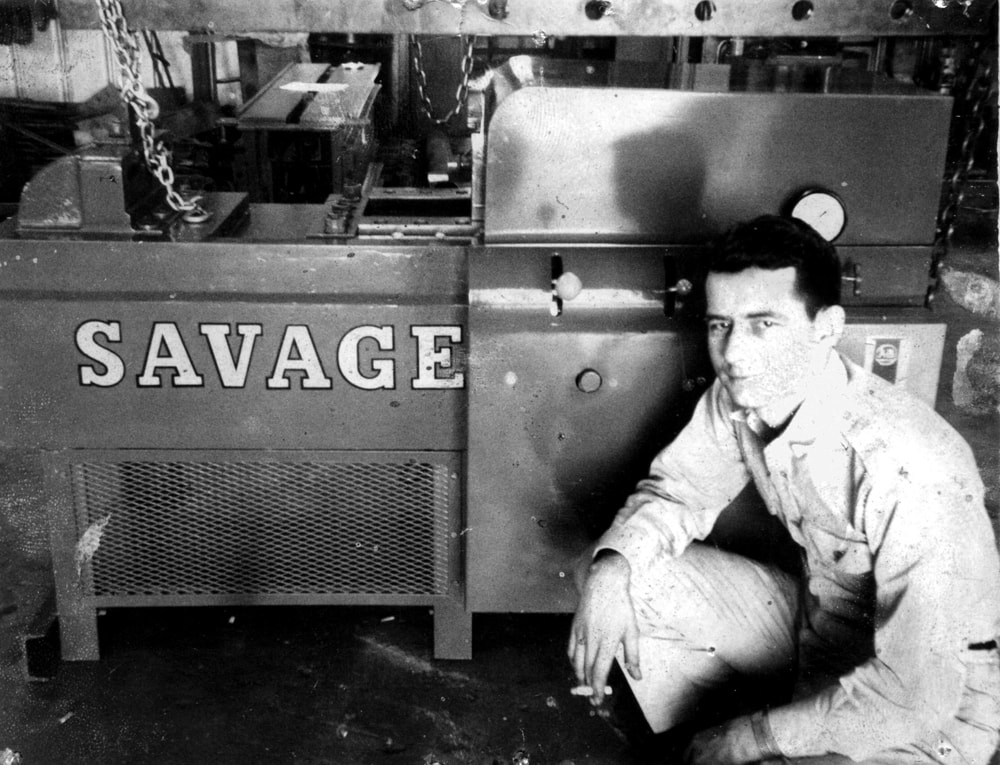

Savage Engineering was founded in 1963 by Fred A. Wolbert. Through a background in automotive, heavy construction equipment mechanics, and industrial sales, he developed an innate understanding of mechanical principles and applications. When a need arose from his customers in the construction equipment industry, Fred saw an opportunity to combine his problem-solving abilities and his technical know-how.

The industry needed presses for bulldozer track repair. The demand was for presses that could both de-pin and reassemble the tracks, and customers looked to him for a solution. In the first year alone, Fred designed, built, and sold over 30 track pin presses.

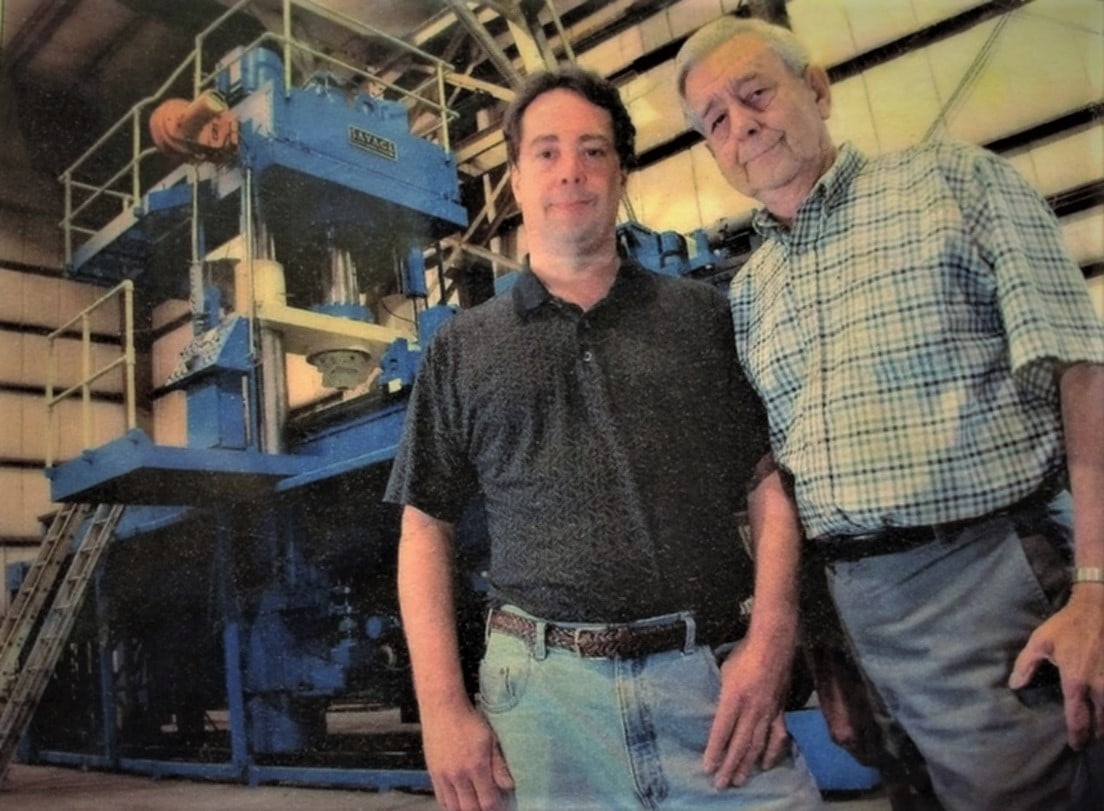

In response to repeated requests from multiple industries for job-specific solutions, Savage Engineering began to expand in size and scope, broadening our concept to help a wide range of manufacturing industries achieve success. Fred’s son, Dan, joined the company in 1975, working first on the shop floor and then alongside his father at the helm before becoming President in 2007.

Savage provides hydraulic presses to both national and international clientele. All our machines are manufactured in our 45,000 square foot facility in Cleveland, Ohio, with convenient access to interstate roads, railways, and an international shipping port. Our presses are proudly designed, engineered, and built entirely in the USA.

We are not a niche market builder, so tackling new concepts is our bread and butter. From sizing and compacting frozen fish or advanced composites to handling radioactive materials safely, or even compacting explosives in smart bomb warheads, Savage will “Job Engineer” a press to fit your specific challenge. Contact us today to learn more!

Conceptualization to Completion – Our Process

First, we start with a discussion of the process and / or parts you are looking to produce, repair, innovate, or improve. We evaluate all aspects of your application for accuracy and reproducibility, and tailor an equipment design.

We will present you with a quote developed specifically for your application. Optional upgrades to further streamline your machine’s utility, speed, and ability to change tooling quickly are also available. Stress analysis assures design integrity, and high-quality build materials are a Savage standard; from chrome tie rod ends and elongated brass bushings to robust steel frames, our press frame designs have a lifetime guarantee to exceed the structural demands of your application and increase the lifespan of your press.

Upon design acceptance, production begins. Steady communication throughout the build process assures that your equipment remains aligned with your needs, and in-build modifications are possible, should the need arise. Factory acceptance testing is performed on-site in our facility. Once build, testing, and run-off are complete, our team will tear down and ship your machine to your door. We also offer on-site installation and training, and technical support is available free-of-charge throughout the operating life of your press.

Your business is unique. Why use a machine that isn’t?