Hydraulic Hot Press Machine

What Is A Hydraulic Hot Press?

A hydraulic hot press is a machine that contributes to the manufacture of aircraft components from titanium or stainless steel alloys. Crystal forging presses support the nuclear and medical equipment industries. We manufacture superplastic forming presses for hot forming of nickel-based alloys, specialty alloys, and superplastic forming of titanium. Hydraulic hot press machines are available for forging and extruding crystals. Hot Presses feature an integral furnace to apply forming pressure at up to 1800°F.

Hot Press

The Savage Hydraulic Hot Press Machine features a powered refractory heat shield or furnace walls that enclose the heated platens on all four sides and microprocessor temperature controls. Suitable for Diffusion Bonding applications. Shuttle beds available. Bed sizes and daylight openings are to your specifications.

The 100 ton Hot Lab Press (left) is used for forming titanium aircraft parts. Alloy sheet is heated in the press to its superplastic state then formed with controlled gas pressure into complex shapes, ducts, and structures.

Catalog Information on Hot Presses

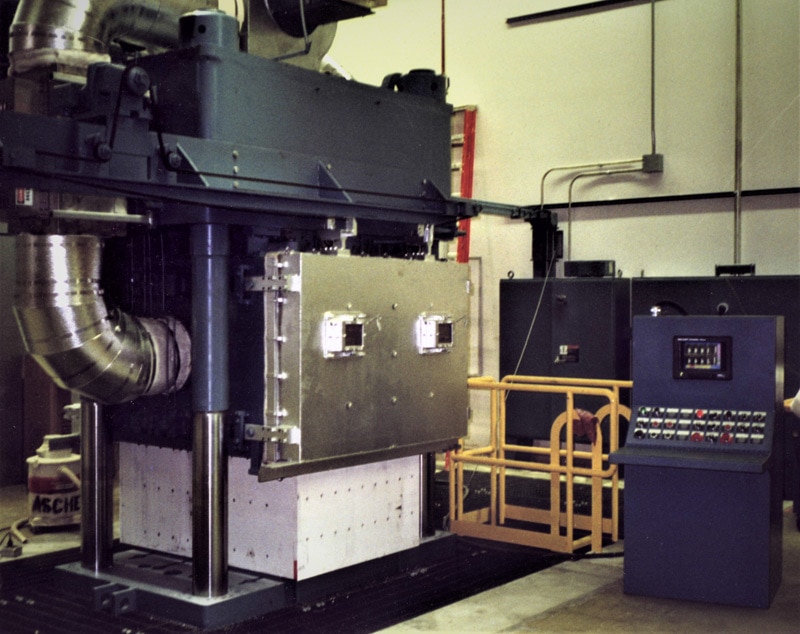

Hot Press with Shuttle Bed

Savage’s Shuttle Bed Hot Presses are designed presses to allow the lower half of the furnace to ride on the shuttle for improved access. It is used with a manipulator loader. Load cells and optical pyrometer information is sent to remote data storage.

This 100-ton model (left) is installed at Martin Marietta.

Catalog Information on Hot Presses with Shuttle Beds

Hot Up-Acting Presses

Hot Up-Acting Presses can forge/flatten large-diameter crystals into lenses for MRI imaging machines. This specific press (left) closes at a controlled rate of .004 IPM to prevent fracture of the crystal. Includes stainless heated platens and recirculating heated air.

This 500-ton model (left) is installed at Siemens Medical Systems.

Catalog Information on Up-Acting Hot Presses

Hot Straight-Side Presses with Pre-Stressed Housing

These hydraulic hot press machines are equipped with a rigid, sturdy frame with pre-stressed tension members that are resistant to frame bend due to extreme temperatures. Pre-stressed housing assures consistent platen parallelism over long periods of use.

This rugged 400-ton model accommodates the customer’s tooling and features hydraulics mounted overhead in a maintenance mezzanine.

Catalog Information on Hot Straight-Side Presses

Available Frame Types:

- Hot Press

- Hot Press with Shuttle Bed

- Hot Up-Acting Presses

- Hot Straight-Side Presses with Pre-Stressed Housing

Capacities

Tonnage and Bed Sizes are Designed to Meet Your Requirements

Designed to Fit YOUR Application

Savage superplastic forming presses combine precision force generated by the ram force with a furnace to maintain a constant temperature. These machines are used for hot forming, hot flattening, creep forming, and for the superplastic forming of titanium and aluminum alloys. Savage’s Hot Presses feature an integral furnace to apply temperatures up to 1800ºF.

- The powered refractory heat shield or furnace walls enclose heated platens on all four sides

- Up to 1800ºF electric heating

- Down-acting clamp capacities to customer specifications

- Bed sizes and daylight openings to customer specifications

- Microprocessor-based temperature controls

- Diffusion Bonding applications

- Made in the USA

Savage does not stock catalog sizes. Each press is engineered to your specifications to perform your job at maximum efficiency.

Industries Served

- Aerospace

- Medical Devices

- Metal Forging

Client History

- Drop Dies and Forgings

- Ensign Bickford A&D

- GE Aviation

- Griner Engineering

- Martin Marietta

- Ohio State University

- Siemens Medical Systems

- TECT

- TRW

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE-PRONE CASTINGS ARE USED IN ANY OF OUR PRESSES.

CONTACT US NOW to Discuss Your Application