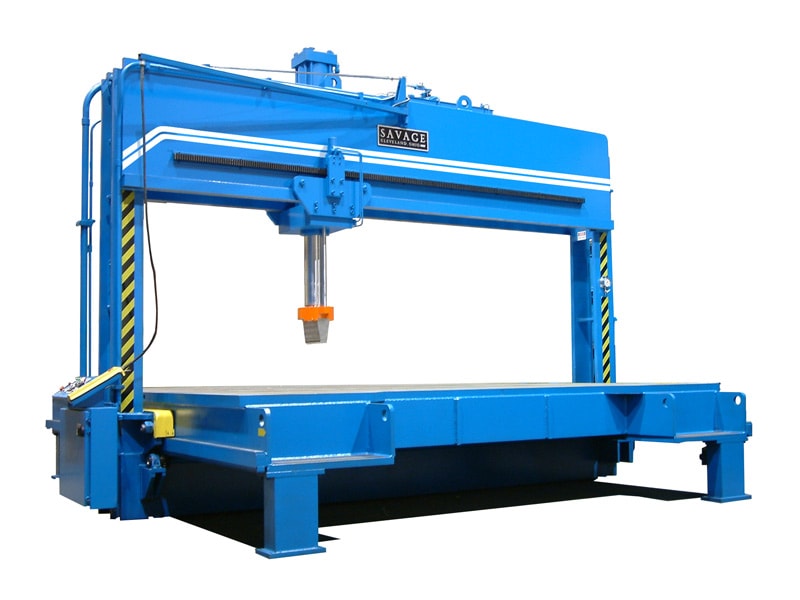

Custom Weldment Straightening Press

Traveling Gantry Wide Bed Press

Available in 100 ton to 2000 ton capacities, our Wide Bed TFS Custom Weldment Straightening Presses with three axes of ram movement are specifically designed for straightening or bending large plates, castings, or weldments. The travel design of the gantry allows the workpiece to remain stationary while the pressing ram traverses to the high spot, eliminating frequent repositioning of large, heavy workpieces.

The Savage Wide Bed Traveling Gantry is a three-axis style of press designed for straightening large plates, weldments, and burned shapes. These sturdy machines are rigid enough for full tonnage across the entire bed. The three axes of movement provide full ram coverage of the bed, eliminating the need to reposition heavy workpieces.

Additionally, hydraulic work lifts can be installed in the bed to assist in positioning the pressing blocks under the work. These work lifts free up overhead crane usage.

Industries Served

- Mining

- Railroad

Catalog Information on Traveling Gantry Wide Bed Presses

Capacities

Tonnage and Bed Sizes are Designed to Meet Your Requirements

Designed to Fit YOUR Application

Savage Wide Bed Straightening Presses are used for the straightening of plates, weldments, and castings.

- Easy operation

- Bed size, daylight opening, throat depth, speed, and stroke available to meet any requirement

- .001” stroke control for accurate ram positioning and preventing over-bending the workpiece

- Ergonomic operator’s control station

- Rugged, computer-designed frame for low-stress levels

- Self-contained hydraulics

- Feed equipment available

- Made in the USA

Savage Engineering does not stock catalog sizes. Each hydraulic plate straightening press is engineered to your specifications to perform your job at maximum efficiency. Contact the team today to learn more about our custom weldment straightening presses.

Client History

- Allan United

- Beloit Corporation

- Blaw Knox

- Dynamic Materials / NobelClad

- FMC Arabia

- GE Aviation

- GOI / MOD

- Kurtz Steel

- Progress Rail Services

- Watt Carr / Bucyrus

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE-PRONE CASTINGS ARE USED IN ANY OF OUR PRESSES.

CONTACT US NOW to Discuss Your Application