Die Spotting Press

Die Spotting, Mold Spotting, & Die Tryout

The Savage Hydraulic Die Spotting Press is available with different options for different budgets. Our basic Die Spotting Press includes a shuttle bed for crane loading dies/molds. It also permits work to be performed on the bottom half of the tool safely outside of the press. For greater tool access, these die tryout presses are available with a 90o or 180o swing-out platen to separate the die/mold halves. The 90o swing-out platen press allows simultaneous repairs of mold halves at two sides of the press. The 180o swing-out platen press inverts the upper half of the tool and presents the tool halves side by side, safely outside of the press. Once examined, the press reassembles the tool for accurate, controlled die spotting.

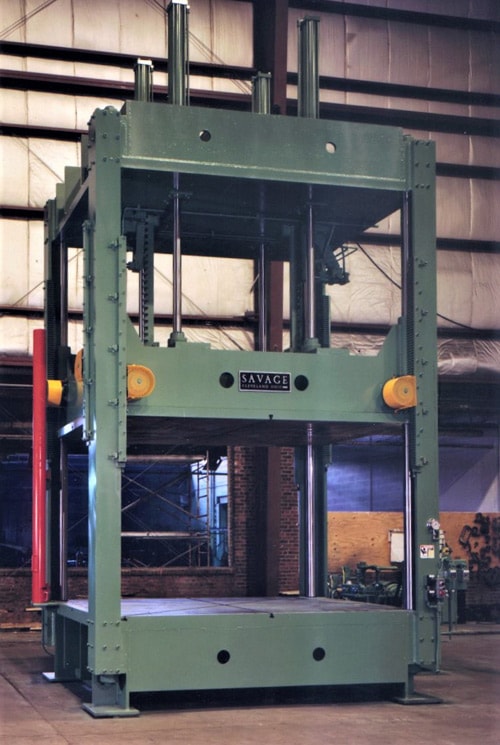

Die Spotting Press

The basic model of Die Spotting Press allows for easy loading/unloading and offers a generous bed size and daylight opening to meet your application’s requirements, with lever or joystick controls and compressed air quick-disconnects for tools.

This 100-ton model (left) features a 123″ x 84″ workspace with ample room for die changeover and repair.

Catalog Information on Die Spotting Presses

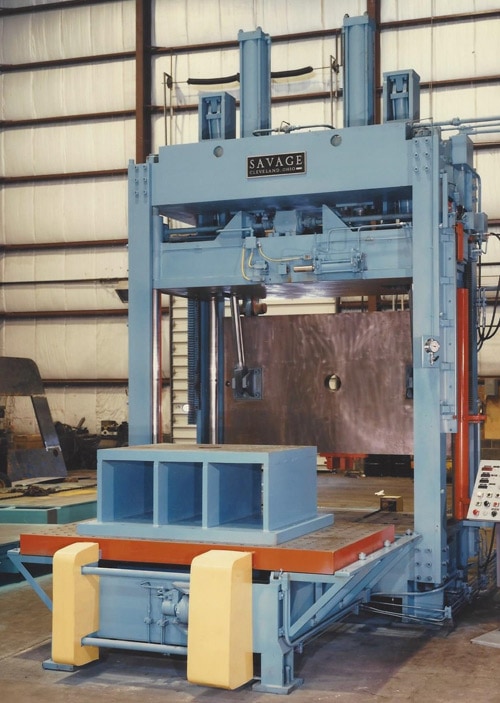

Die Spotting Press with 90o Swing-Out Platen

The rear swing-out platen allows for correction and grinding operations without interfering with similar operations performed simultaneously at the front of the press on the opposite die half.

This 100-ton model (left) uses a frontal shuttle table to load tools and allow work on the lower tool halves and features a 90-degree upper swing-out platen facing rear to allow access to the upper tool.

Catalog Information 90o Swing-Out Die Spotting Presses

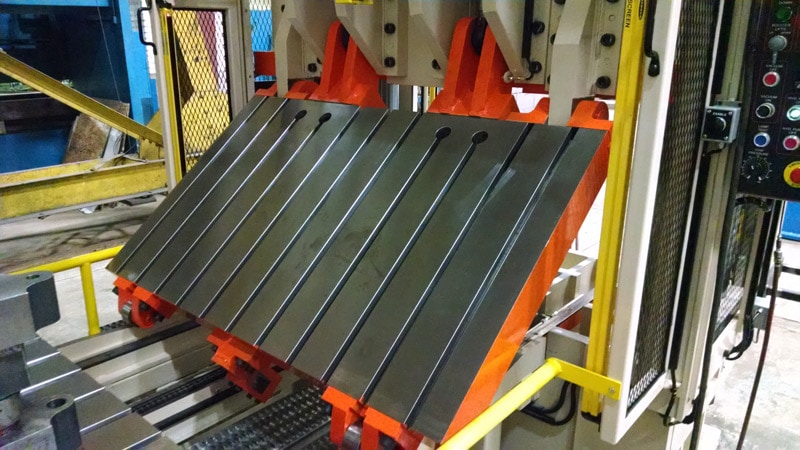

Die Spotting Press with 180o Swing-Out Platen

Savage’s 180o Mold and Die Spotting Presses are precision-guided hydraulic presses for the off-line repair of dies and molds that help eliminate the bottleneck of tying up your production press.

This 100-ton model (left) features a 180o frontal swing-out platen, shown here in full inversion mode along with the frontal shuttle table. 180o inversion permits booking open injection molds by placing them face-up, side-by-side, for comparisons and repair.

Catalog Information 180o Swing-Out Die Spotting Presses

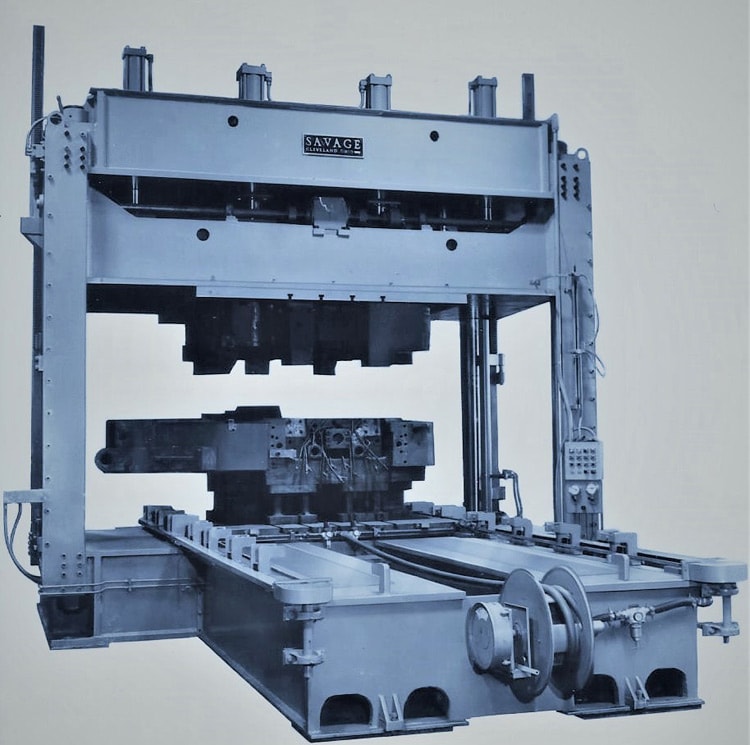

Die Spotting Press with Rolling Bolster

The Die Spotting Press with Rolling Bolster offers bed sizes, daylight openings, and down-acting clamp capacities to your specification with the option for a T-slotted bolster or T-slotted shuttle bolster. Shuttle bolster allows for easy crane loading of dies and molds.

The 100-ton model (left) spots aluminum die casting dies up to 60,000 lb. Frontal shuttle bolsters with 168” x 96” opening between the uprights allows for easy loading, and lower die repairs outside of the press. Shown with 30 ton die casting die.

Catalog Information on Die Spotting Presses with Rolling Bolster

Available Frame Types:

- Die Spotting Press

- Die Spotting Press with 90o Swing-Out Platen

- Die Spotting Press with 180o Swing-Out Platen

- Die Spotting Press with Rolling Bolster

Capacities

Tonnage and Bed Sizes are Designed to Meet Your Requirements

Designed to Fit YOUR Application

Our die spotting presses offer significant safety improvement to using cranes and chains for overhead lifting. Available in different types for different budgets. Models and sizes to fit your molds and dies.

- Front or Rear (90o / 180o ) Swing Out Platen

- 50 to 300-ton capacities

- Four corner stabilization bars

- Powered roll-out lower shuttle bolster

- Ram stroke control to ±.001″ allows ‘kiss’ contact

- Tonnage, bed size, daylight, and stroke to your requirements

- Remote pressure and speed controls

- Extra-long bronze guides

- Safety platen latches (standard)

- Safety swing-in platen blocks

- Lower 45¼ tilt-up bolster (optional)

- Motion controlled leveling

- Made in the USA

Save time and money with an efficient solution to outdated spotting methods.

Savage does not stock catalog sizes. Each die tryout press is engineered to your specifications to perform your job at maximum efficiency.

Industries Served

- Automotive

- Electronic Components

- Industrial Vehicles

- Medical

Client History

- Exco

- Denso

- Doehler Jarvis

- GM

- Metalsa

- Nippondenso

- Volpex Corporation

ALL SAVAGE HYDRAULIC PRESSES UTILIZE STRESS-ANALYZED FABRICATED WELDMENTS –

NO BREAKAGE-PRONE CASTINGS ARE USED IN ANY OF OUR PRESSES.

CONTACT US NOW to Discuss Your Application