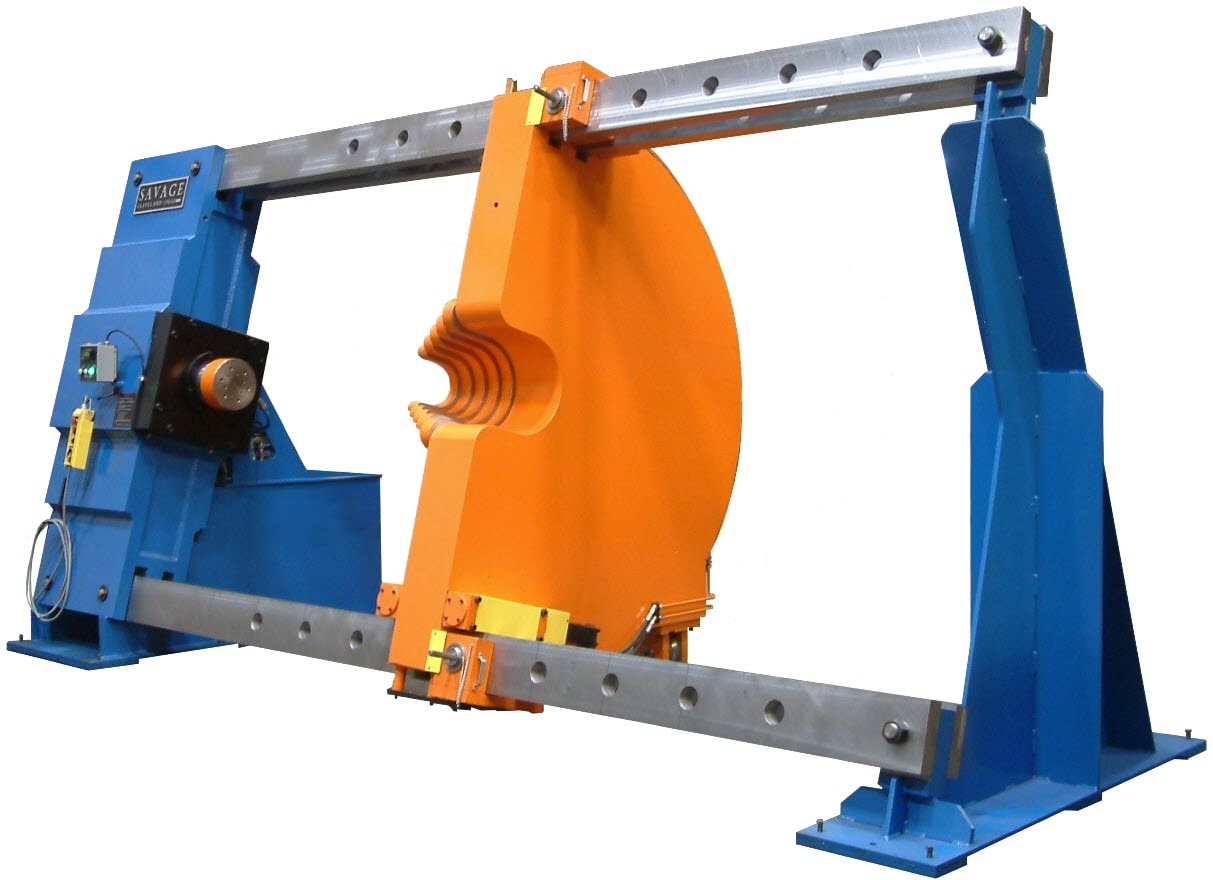

Horizontal Forcing Wheel Press

For Pushing /Pulling Wheels, Sheaves, Gears, etc., Onto / Off of Shafts, Rolls, Axles, and Armatures

What Is A Horizontal Forcing Press?

The Horizontal Forcing Press also referred to as a Wheel Press, plays a crucial role in “repair-based” industries and applications.

- Rotor shaft removal for the electric motor repair industry

- Pumpjack crank arm repair for the oil and gas industry

- Numerous component repairs for the mining industry

- Sheave/drum repair for the crane industry

- Wheelset maintenance for the railway industry

Adding a second “opposed ram” creates a dual-ram design, equipping this frame type to mount and dismount all the components of a rail car wheelset (wheels, brake discs, gears, and bearings) onto and off of rail car axles during routine maintenance and repair. Savage offers a variety of hydraulic horizontal forcing presses such as the horizontal forcing wheel press and the hydraulic horizontal bulldozer press.

Horizontal Forcing Wheel Press Highlights

- Hydraulic motor positioning drives the roller-mounted bolster along the lower set of twin rails is far superior to previous generations of wheel presses

- Inclined frame offsets the upper and lower rails at a 75o angle, allowing clearance for workpieces to be loaded via overhead crane

- The integral 2-speed hydraulic power unit enhances productivity with high-speed advanced press modes

- Extra-long stroke lengths (up to 36″) minimize the need for bolster relocation

- Ram control features automatic pressure hold

- Heavy-duty four-rail construction minimizes stretch

- Open-ended design accommodates work of infinite lengths

The Savage Dual-Ram Wheel Press design incorporates the following features and options for heavy rail or light rail vehicles:

- Slim-profile bolster affords more space L-R for bulky components

- Available with powered Wheelset Support Table to ease insertion and positioning of wheelset during assembly/disassembly

- Dual pressing rams service both ends of the axle, eliminating the need for wheelset repositioning

- Programmable controls and data recorder

Features and Benefits

With over five decades of design experience, certain features which increase the versatility of the machine have become standard on every Savage Single Ram Wheel Press:

- A slim-profile, solid steel strong back bolster replaces the customary wide-width, bulky yoke (traditionally a fabrication or casting), creating more space for awkward and difficult workpieces

- A corded pendant enables the operator to walk alongside the strong back bolster

- Powered bolster rollers traverse the twin rails, eliminating the traditional, cumbersome practice of tugging the bolster into position with an overhead crane

- Removable ram nose tool

- Bolster stop blocks with attached lock pins eliminate pin lifting and increase safety

- End leg clearance opening accommodates workpieces of infinite length

A Press Solution That Fits YOUR Needs

At Savage Engineering, we customize every hydraulic horizontal press to meet our customers’ requirements. Based on your application, we provide customized:

- The vertical distance between rails

- Daylight opening

- Tonnage

- Stroke

- Left or right cylinder mounting for single ram presses

- Special options, features, and custom tooling

- Automation and custom tooling

Options and Upgrades for Single Ram Horizontal Presses:

- Wireless Remote Control provides the operator with infinite vantage points during operation

- Powered Upper and Lower Bolster Lock Pins enhance production cycle times and increase safety

- Adjustable Charlie Bars accommodate a range of smaller shaft diameters

- Digital LED Display to show actual tonnage in real-time

- U-slot reducers (provided in 2″ increments) for centering different shaft diameters

Options and Upgrades for Dual Ram Horizontal Presses:

- Programmable Ram Tonnage and Ram Position

- Automation of Components

- Axle Staging and Delivery

- Wheel Staging and Delivery

- Bearing Staging and Delivery

- Laser Measurement of assembly and data logging

- Custom Tooling and Storage Solutions

- Special Options and Equipment

The Savage Engineering Difference

For nearly 60 years, Savage Engineering has been designing and building high-quality, durable hydraulic presses to meet each customer’s unique needs and exact job specifications. Our process is fully integrated from concept to delivery. You’ll receive onsite installation, training, and technical support throughout the operating life of your press.

All Savage presses are made in the USA. We are committed to your complete satisfaction and success. Let us design the machine your business deserves!